Museum Artifact: Elgo American Plastic Bricks set No. 705 (1950s) and Halsam Double Twelve Club Dominoes (1960s)

Made By: Halsam Products Co., 4114 N. Ravenswood Ave., Chicago, IL [Ravenswood]

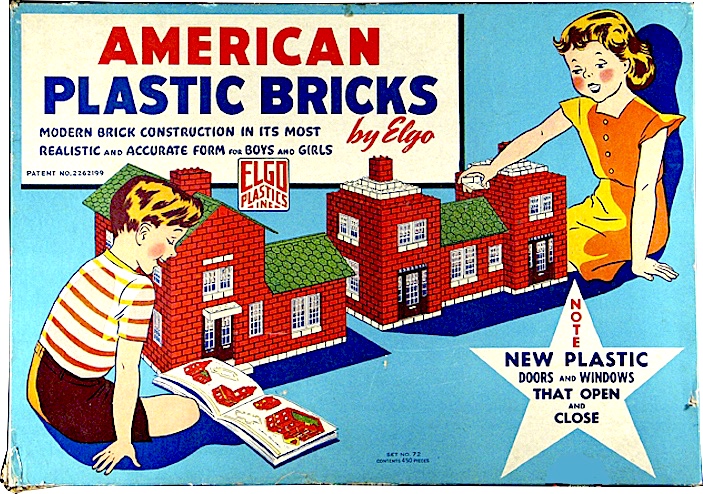

Upon encountering an old cylindrical cardboard container of “American Plastic Bricks by Elgo,” nine out of ten people are likely to make the same spontaneous assumption—that they’re looking at a cheap knockoff of LEGO.

. . . And a lazy one at that. I mean . . . ELGO? It’s a bit on-the-nose for a toy set involving rectangular interlocking plastic building-blocks, ain’t it? Did they really think they could just swap the first two letters of the name and shamelessly piggyback off the success of those ingenious Danish toy pioneers over at the LEGO Corporation—the one brand forever synonymous with this genre of children’s entertainment?

Well, as it turns out, the classic copycat narrative isn’t quite as cut-and-dried here as it first appears. For an accusation of plagiarism to stand up in court, the chronology of the two items in question is just as important as any comparison of their content. And in the case of our Chicago-made American Plastic Bricks, the timeline reveals a surprising truth that flies in the face of our pop-cultural presumptions. That’s right, folks. It was ELGO, not LEGO, that built its bricks first!

In what has to rank as one of the more bizarre semi-coincidences in the history of registered trademarks, ELGO Plastics, Inc. was actually established as a division of Chicago’s Halsam Products Company in 1941—long before LEGO entered the American marketplace (1961). Odder still, the inter-locking toy bricks developed by Halsam / ELGO were introduced in the late 1930s, pre-dating LEGO’s foray into that same field (1949’s “Automatic Binding Bricks) by a full decade.

Everything may be awesome in Legoland, but original? Not so much.

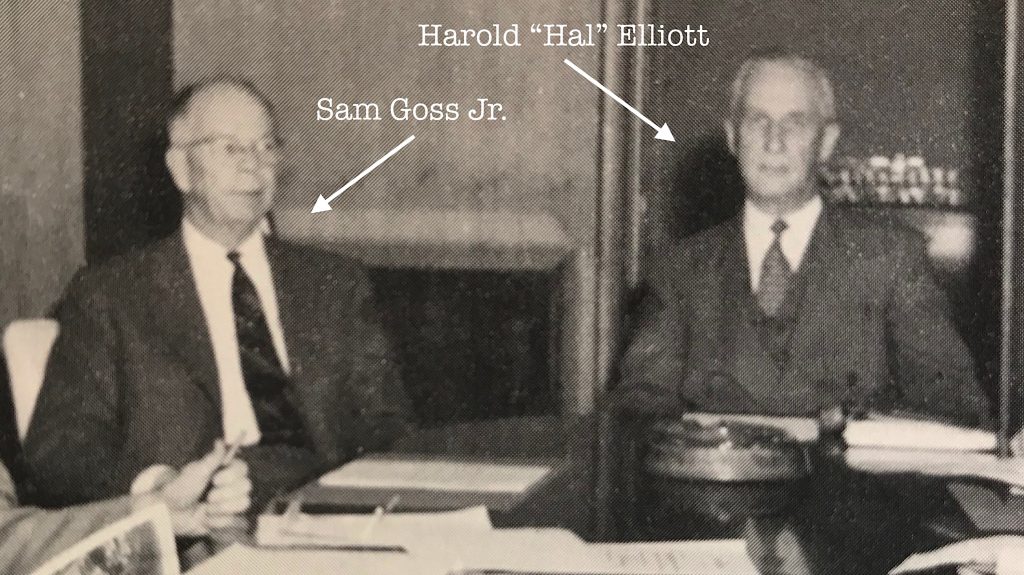

In fairness, it seems that both the Danes and Americans came to their eerily similar identities quite independently. In Denmark, the “LEGO” name had been put into use with the company’s early wood toys as a reference to the phrase “leg godt,” meaning “play well.” Meanwhile, in Chicago, established toy makers Harold “Hal” Elliott and Samuel Goss, Jr. chose to name their new plastics business after themselves: combining the EL from Elliott with the GO from Goss (hence, EL-GO!).

This was standard operating procedure for the duo, mind you, as they’d started their original toy business back in 1917 by using the same cutesy taxonomical technique: HAL Elliot + SAM Goss = HALSAM Products.

[Halsam Products / Elgo founders Sam Goss Jr. and Harold Elliott at a board meeting in 1953]

[Halsam Products / Elgo founders Sam Goss Jr. and Harold Elliott at a board meeting in 1953]

History of Halsam Products Co., Part I: Hal and Sam

Before becoming business partners, Hal Elliott (1886-1973) and Sam Goss Jr. (1896-1976) were already family; brothers-in-law to be precise. Hal, a former clothes dealer and insurance salesman, married Sam’s sister Hazel Goss in 1915, putting the two men literally under the same roof for several years at the stately Goss family home in the north suburb of New Trier.

Back then, Hal was known by his birth name, Harold Elliott Hirsch—the German surname having come over with his grandparents. After World War I broke out, however, he elected to swap the order of his middle name and last name as a safeguard against growing anti-German sentiments. He would be Harold H. Elliott from that point forward.

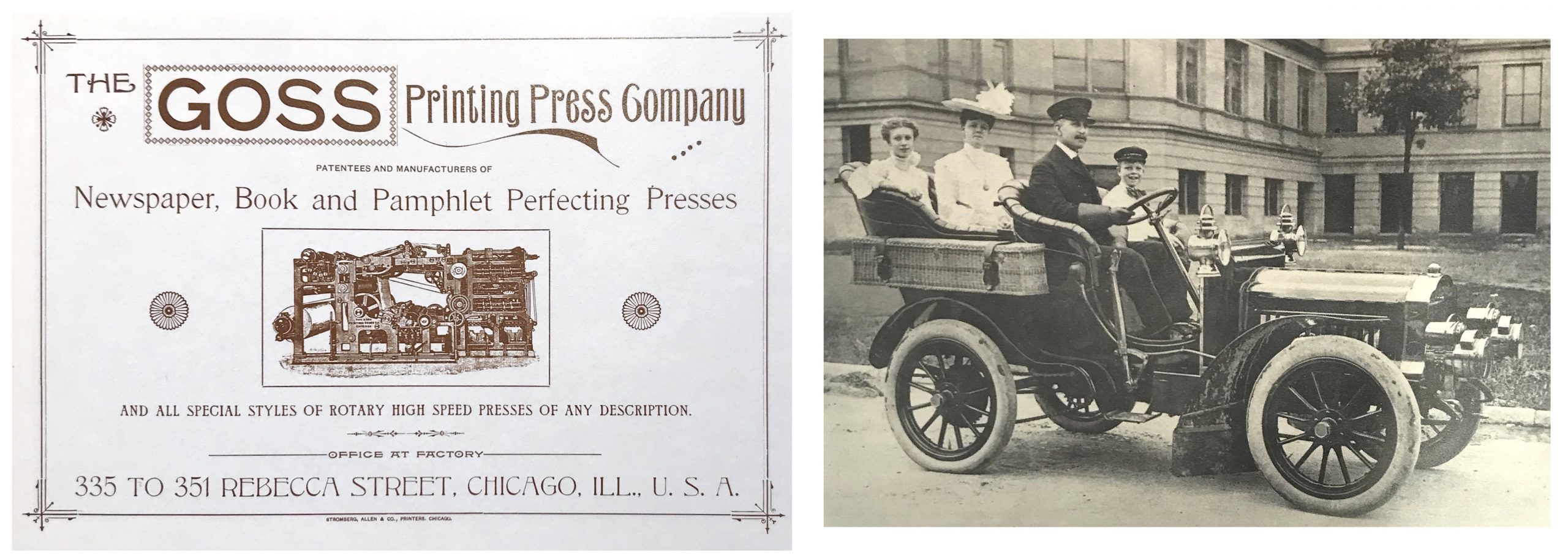

[Left: Advertisement for the Goss Printing Press Co., circa 1900. Right: Sam Goss Jr., as a boy, riding shotgun beside his father Sam Goss Sr. on the South Side of Chicago, circa 1905]

[Left: Advertisement for the Goss Printing Press Co., circa 1900. Right: Sam Goss Jr., as a boy, riding shotgun beside his father Sam Goss Sr. on the South Side of Chicago, circa 1905]

Sam Goss Jr., like Elliott, was a second generation American (in his case, of English stock), but he’d been raised into wealth, rather than marrying into it. His father Samuel Goss, Sr. and uncles Frederick and William Goss were the founders of Chicago’s Goss Printing Press Company—known for an innovative “Straightline” rotary press that had become the standard of the newspaper industry in the early 20th century.

As Sam Jr. came of age, the obvious progression would have been for his father to simply groom him—and his new brother-in-law Hal—for long term positions in the family business. And indeed, both young men would eventually serve on the board of the Goss Printing Press Co. Before his death in 1922, however, patriarch Samuel Goss Sr. seemed quite intent on seeing the next generation build something of their own first; a business wholly outside the printing industry. Maybe it was the uncertainty of World War I that was the motivating factor, or a nostalgia for the simpler distractions of youth. Either way, the building blocks were soon laid for Sam and Hal’s new venture, and coincidentally, it involved building blocks.

II. Chip Off the Old Blocks

By most accounts, Hal Elliott and Sam Goss Jr. officially organized the Halsam Products Company in 1917; hence the HAL-SAM name. But according to historian Herman Kogan’s 1985 book Goss: Proud of the Past, Committed to the Future—a history of the Goss Printing Press Co.—it was really Samuel Goss Senior who got the ball rolling, essentially handing his kid the keys to a factory and arranging most of the furniture therein.

“Early in 1917,” Kogan writes, “as a hedge against possible economic slowdowns, [Goss Sr.] had purchased a small toy factory in Muskegon Heights, Michigan, which specialized in hand-crafted wooden A-B-C blocks for children. His partner was his son-in-law, Harold Elliott, so the name affixed to the company was Halsam.”

Kogan acknowledges that Sam Sr. subsequently handed off the daily operations of the toy business to Elliott and young Sam Jr., and that the Michigan factory was promptly removed to Chicago at 4114 Ravenswood Avenue. But this still conflicts with the notion that Sam Jr. was the original “SAM” in the HALSAM equation. Kogan goes a step further, too, crediting the elder Goss Sr. with not only buying the toy business, but coming up with the “vital contrivance” of the new enterprise, as well.

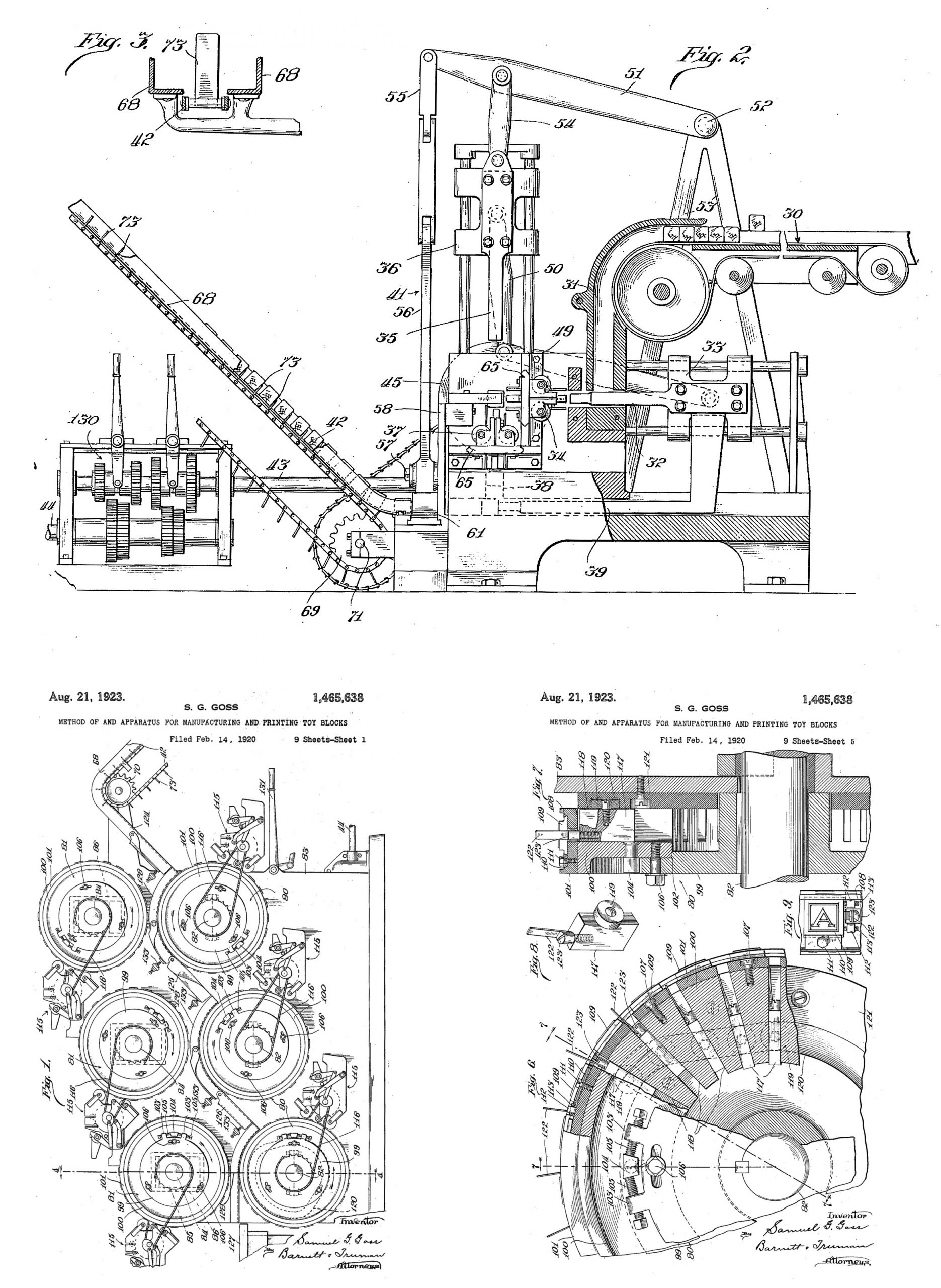

“Using basic principles of printing presses,” he writes, “[Goss Sr.] designed a machine that stamped letters on the blocks automatically and increased their output a thousand-fold and more.”

The 1961 book Toys in America refutes this, giving credit to the prodigal son, Sam Goss Jr., for applying the technology of his dad’s industry into the toy trade:

“Since his father had been a manufacturer of rotary printing presses for newspapers,” the author states, “it was natural for [Goss Jr.] to adapt the principles of such a press to a continuous column of wooden blocks instead of a sheet of paper.”

[Several drawings from a 1920 patent application, by Samuel G. Goss (no “Junior” or “Senior” specified), for the “Method of and Apparatus for Manufacturing and Printing Toy Blocks.” The patent was approved in 1923 as U.S. patent 1,465,638]

[Several drawings from a 1920 patent application, by Samuel G. Goss (no “Junior” or “Senior” specified), for the “Method of and Apparatus for Manufacturing and Printing Toy Blocks.” The patent was approved in 1923 as U.S. patent 1,465,638]

Whichever Goss you give the credit to [patent records suggest papa], the result is the same: the Halsam Products Company thrived immediately by relying on modern automation and factory efficiency to make quality alphabet blocks and dominoes at a cheap price. By the time Sam Goss Sr. died in 1922, his son and son-in-law had already turned the upstart toy business into a major player on the national scene, gaining significant ground on the former dominant manufacturer of wooden alphabet blocks, the Embossing Company of Albany, New York.

Compared to the Embossing Company’s relatively old-fashioned methods, Halsam’s blocks were produced at a furious pace at the Ravenswood plant, with far fewer workers needed to do so.

“With only two attendants, a single block press turned out 175,000 blocks a day,” according to Toys In America. “And with two such presses, the Halsam plant’s output came to 350,000 blocks daily.

“Another Halsam machine made dominoes with almost no attention from a human being; as the black hardwood blocks moved forward, the varying numbers of white spots were added, and when the dominoes reached the end of the machine, they slid into a box that held the requisite number for a complete set, already sorted. This machine turned out 8,000 complete sets of dominoes each day, and the demand was such that it never stopped working, except for occasional repair and cleaning.”

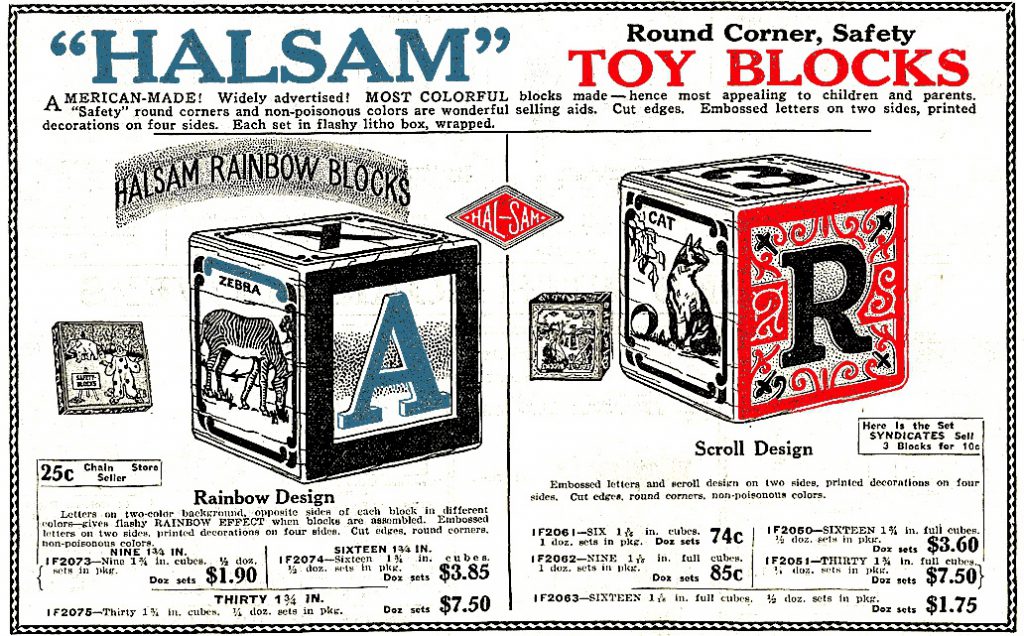

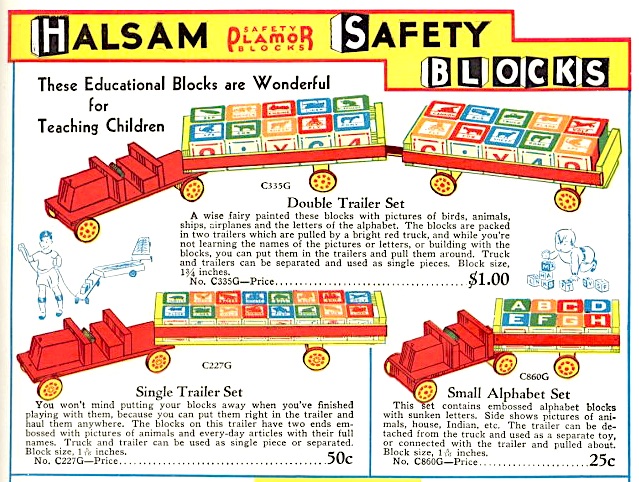

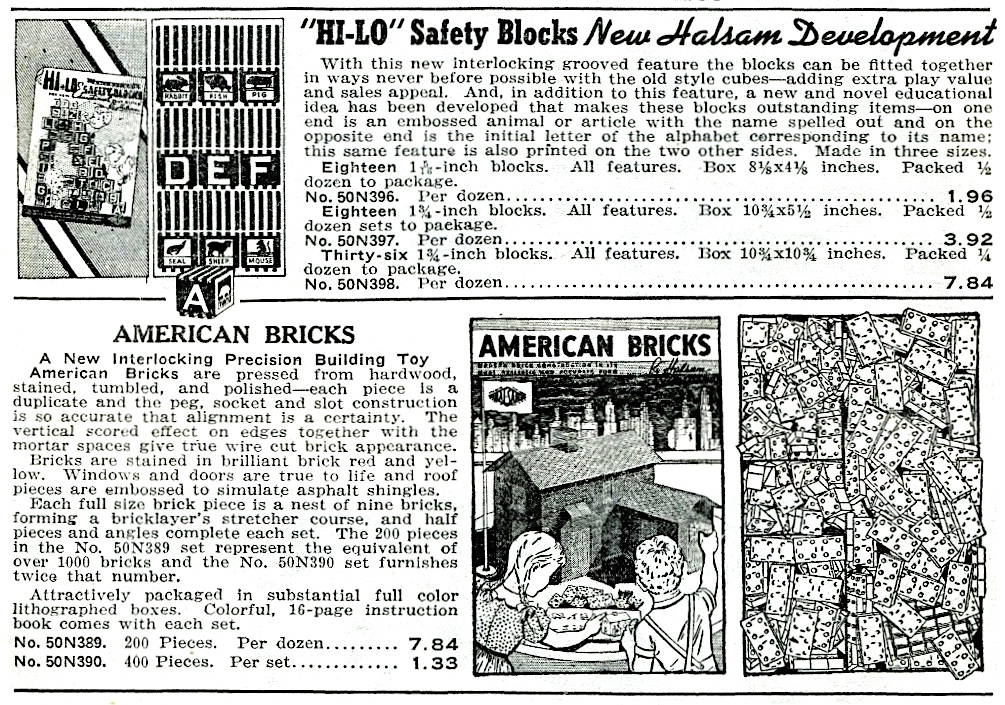

Advanced machinery also allowed for quick innovations. When the toy buyers at Marshall Field’s told Goss and Elliott that some parents were complaining about the sharp corners of their alphabet blocks, the company developed rounded corners and introduced “Safety Blocks” to cleverly address the concerns. In the 1920s, grooves were added with the “Hi-Lo” line of wood blocks, enabling easier stacking. Halsam was already becoming an authority on a whole new generation of “construction” toys.

III. Re-Construction

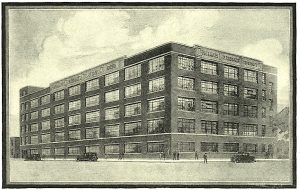

Notably, Halsam’s entire toy line was wood-based during its early years, so when a small fire broke out in the factory in March of 1928, the “large amounts of wood, sawdust, and celluloid” in the building quickly turned the blaze into a raging inferno, costing upwards of $100,000 in damages (about $1.5 million in modern dough). Had this occurred just 18 months later, it might have permanently destroyed the business, as rebuilding a factory after the stock market crash could have seemed like a fool’s errand. Instead, in these final rosy days of the Roaring ’20s, the fire was seen as the impetus for Goss and Elliott to build a whole new plant on the same location, twice the size of the original.

“The new Halsam factory is running at full blast,” read a December 1928 advertisement, suggesting that the re-built, five-story facility had opened less than nine months after the fire. “Our equipment and working conditions are as modern as will be found in any manufacturing institution. . . . Halsam has always been a quality line, and we will not contend that our new modern factory will have any bearing on a better quality . . . our policy has always been to give the best . . . but we do feel that with our increased production facilities, warehouse space and ideal working conditions, we will be better able to serve our many customers and prospective customers.”

The expectation was that Halsam’s new factory would be well equipped to handle continued exciting growth in the 1930s, but as a sobering new economic reality set in, the company soon recognized that it would require more than just slick automation to maintain its gains. Clever marketing and new product development would determine whether penny-pinching American families would still give them their business.

IV. Mouse in the House

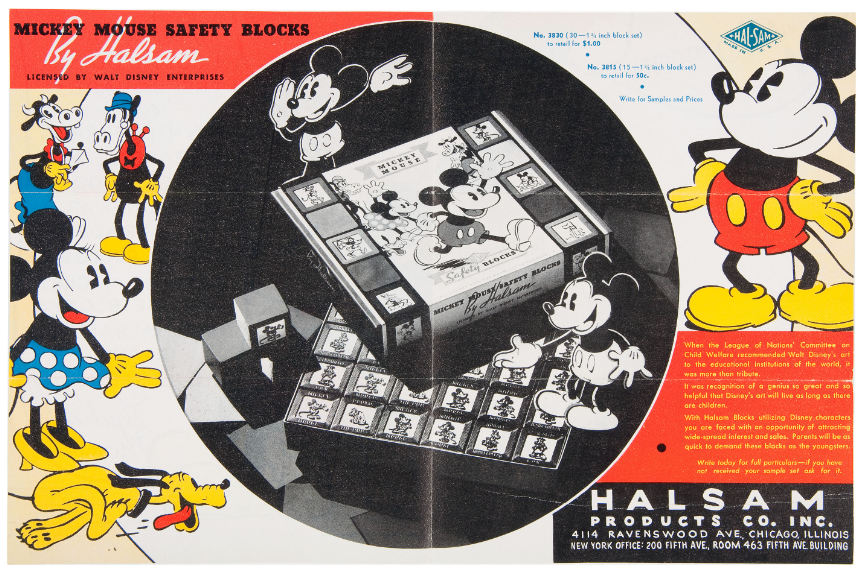

And so, just a few years into the Depression, Halsam became one of the first of many businesses to ink a licensing deal with Kay Kamen Ltd., the new merchandising contractor for the Walt Disney Company. Disney was still an upstart animation studio at the time, but Mickey Mouse was rapidly on the rise, and the use of his image on Halsam’s Mickey Mouse Safety Blocks and Mickey Mouse Dominoes (along with Minnie, Pluto, and others) played at least a small role in establishing the character’s iconic status.

“We feel quite proud of the fact that we have secured the rights to use Mickey and his family,” Hal Elliott told Playthings magazine in 1934. Not only would the character help generate widespread interest and sales, but, as Elliott emphasized, “the Walt Disney Enterprises are very exact in their requirement for licensing and do not allow the use of their characters except on recognized quality lines of merchandise and by well established and reliable manufacturers.”

By 1939, there was even a Halsam toy set called “Disneyland Blocks,” so named nearly two decades before the actual Disneyland theme park opened in Anaheim.

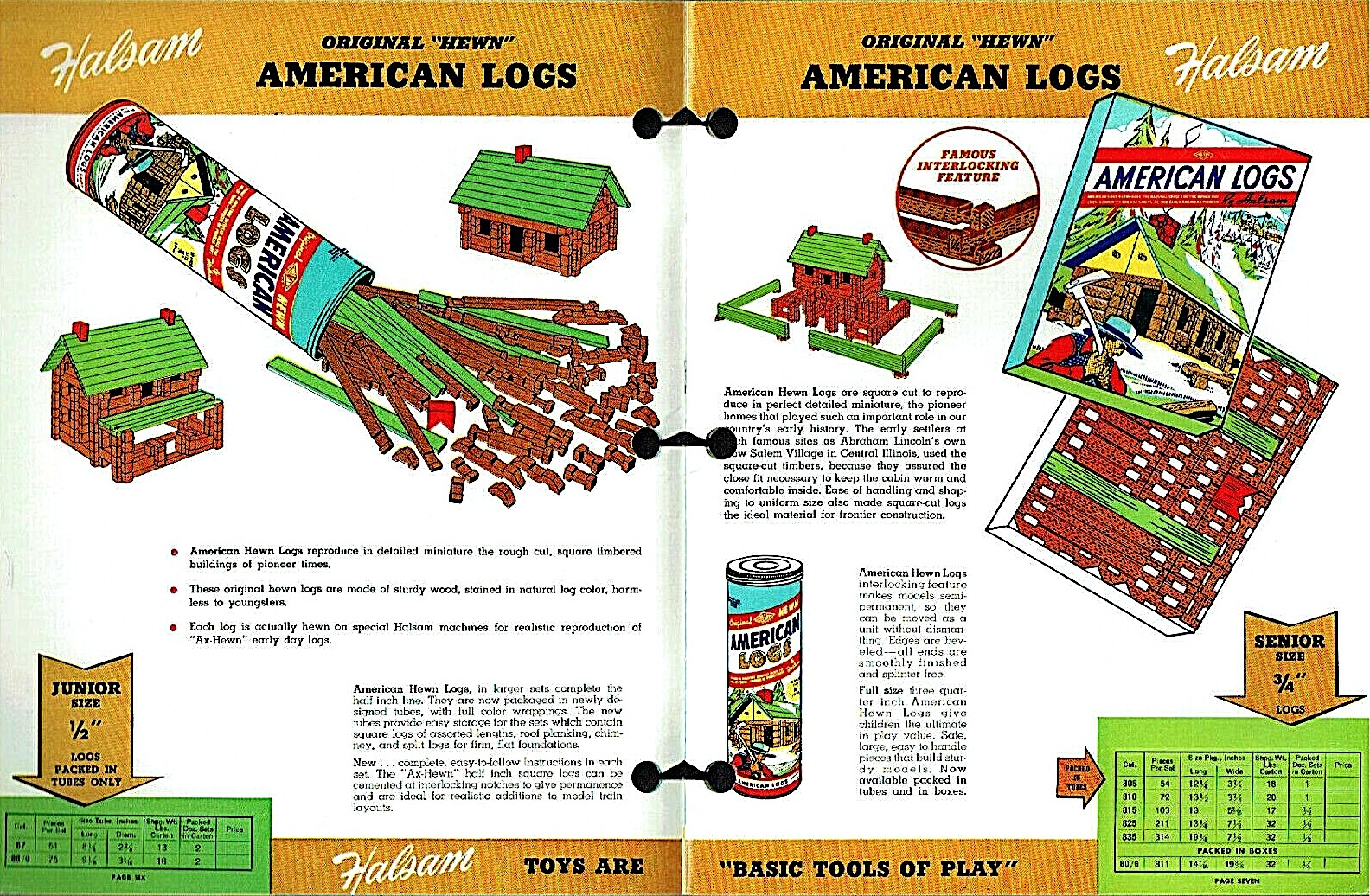

A similar bit of branding ingenuity in the ‘30s can be seen with Halsam’s entrance into the field of “toy building logs,” a genre invented and dominated by Chicago’s Lincoln Logs since the early 1920s.

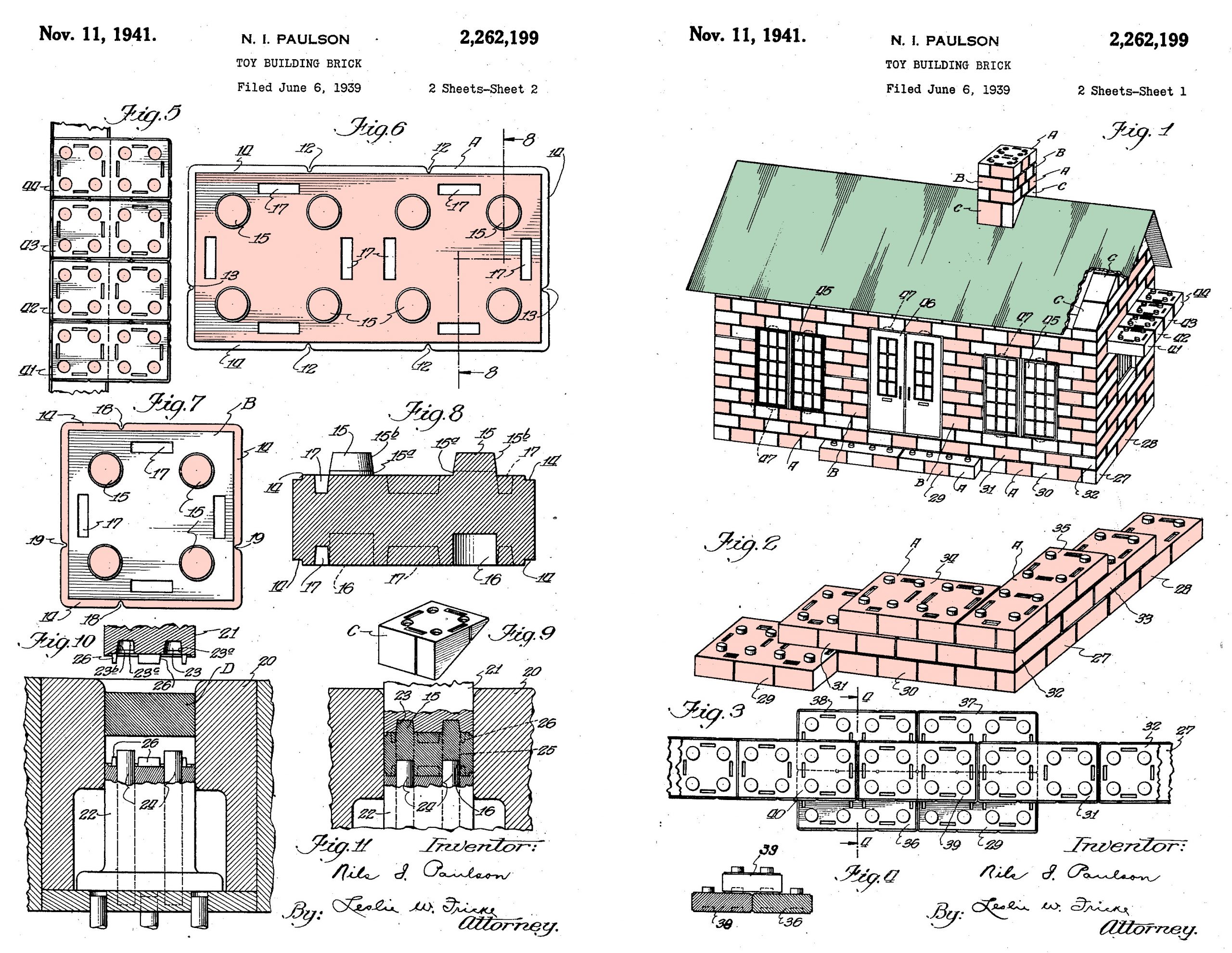

As the story goes, JC Penney had approached Halsam about making a knockoff version of Lincoln Logs, which were being exclusively distributed through Montgomery Ward stores at the time. Goss and Elliott balked at the idea of copying the design, however, and instead recruited a talented Swedish engineer named Nils I. Paulson—a veteran of the Goss Printing Press Co.—to help them make their own, distinct style of stacking log; square-shaped rather than round.

Patented in 1936, Paulson’s square log design was eventually packaged alternately as Halsam’s “Frontier Logs,” “American Logs,” and “Walt Disney Early Settlers Logs,” among other names. Unlike the LEGO scenario described earlier, American Logs were certainly derivative of a more established product. But Halsam’s marketing team had identified a very specific hole in the existing marketplace. Lincoln Logs, from their inception, had never sold well in the South, where the grandkids of Confederates were still dissuaded from touching anything associated with the 16th president (namesake logs included). Thus, when Halsam’s generically patriotic “American Logs” arrived on the scene, they offered no such impediments, and sold well below the Mason-Dixon Line a result.

That was just the first of many successes for Nils Paulson, who would remain a vitally important figure in the Halsam offices for roughly three decades. Besides designing the American Logs and new machines for manufacturing them, he also led the way in the company’s logical evolution from stacking logs to stacking bricks.

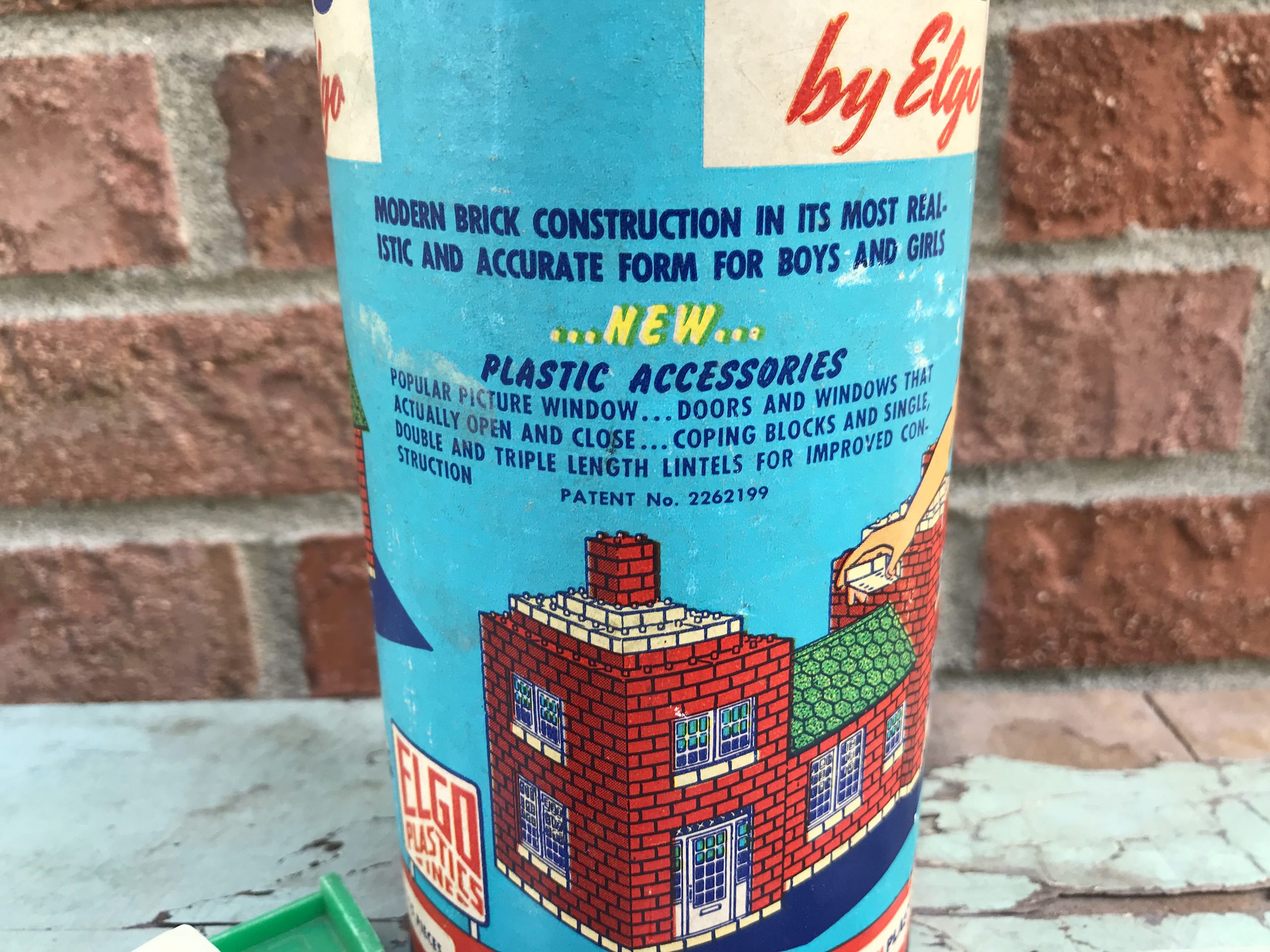

In 1939, Paulson’s patent application for the “toy building brick” described the concept as such: “toy building members in the form of rectangular parallelepipedons, the sides and ends of which simulate in appearance the sides and ends of a plurality of ordinary building bricks.”

Paulson’s brick, which was still made from wood in its original manifestation, also introduced “a new and improved form and arrangement of dowels and sockets . . . whereby any two members of the set may be quickly and easily secured together in the desired relative positions, and yet may be easily separated when it is desired to tear down the structure.”

There had been a handful of inter-locking, socket-style brick toys on the market in the years just prior to this—including the rubberized Bild-O-Brik (made by the Rubber Specialties Co. of Conshohocken, Pennsylvania) and Minibrix; a British version introduced by the Premo Rubber Co. in 1935. None had gained any significant traction (pun intended), however, and the race to perfect the concept was wide open.

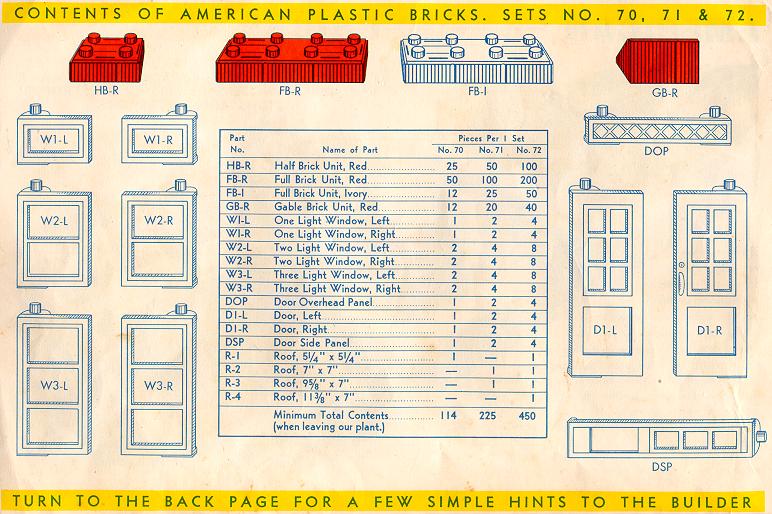

[Above: Nils Paulson’s, “Toy Building Brick,” U.S. Patent 2,262,199, was applied for in 1939 and registered in 1941. By contrast, Lego had just 10 employees in 1939 and didn’t start making its own bricks until 10 years later. Below: A 1940 advertisement in the Nathan Shure catalog for Halsam’s “Hi-Lo Safety Blocks” and the original pre-war, hardwood “American Bricks.”]

V. Hello Elgo

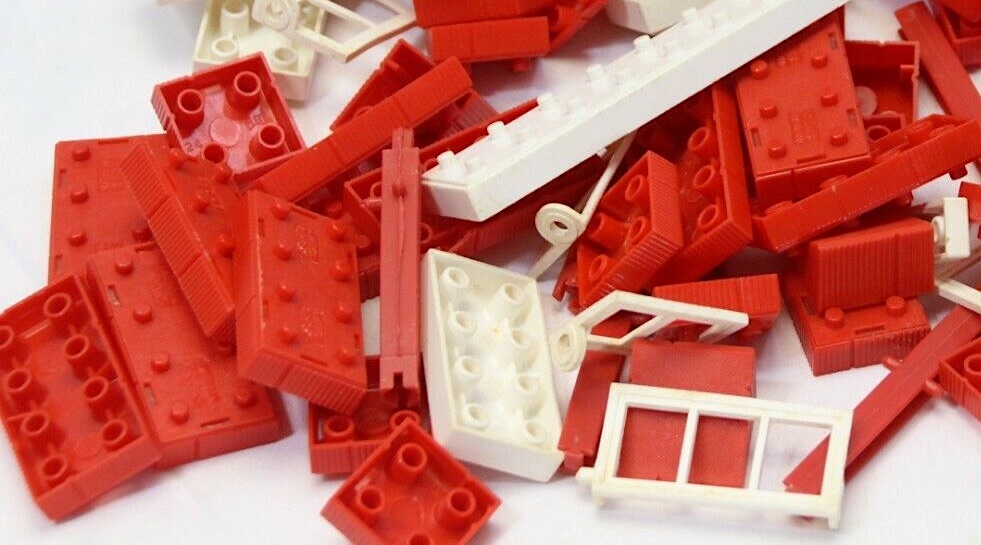

The original run of Halsam’s “American Bricks”—rolled out between 1939 and 1940—were probably more akin to the company’s dominoes than its alphabet blocks or Frontier Logs. All pieces in a set were pressed from hardwood, identical in size and shape, and equipped with a peg, socket, and slot construction—intended to replicate the actual geometry of the brick mason’s trade. From the beginning, the pieces were available in bright reds and yellows, and the full kits included decorative windows, doors, and “shingled” cardboard roofs. Compared to putting together a boring old log cabin, this would have felt like a genuinely awesome leap forward, but in fact, it was more of a hop.

The real leap came in 1941, when Nils Paulson and the Halsam team started a full-scale transition from simple hardwoods to the injected molded plastics of the nuclear age. With early successful experiments making bakelite checkers and dominoes, Goss and Elliott felt confident enough to launch a new division of the company—yup, the pioneering ELGO Plastics—with the next goal of making a plastic version of their interlocking bricks. Elgo’s first offices were located at 1801 Warner Avenue.

American Plastic Bricks were probably ready to hit the market as early as 1942, but the new priorities of wartime America shelved the project, as the Halsam plants shifted mostly into government contract work.

When Halsam and Elgo returned to full-time amusement-making after the war, Paulson and the rest of the R&D team had had plenty of time to consider exactly how a plastic brick building set ought to work. Harold Elliott, who’d lived in England during part of the 1940s while leading the UK office of the Goss Printing Press Co., also reported back on some of the popular British construction toys his son Kip (aka Harold Elliott Jr.) had enjoyed playing with while there, including the aforementioned Minibrix and a superior new entry into the genre, the Kiddicraft Self-Locking Building Brick, which was made of injection-molded plastic. According to some sources, Kip Elliott himself was given an active role in the development of Elgo’s American Plastic Bricks, but in point of fact, he was just 16 years old when the toy first hit the market in 1947, so any real leadership would likely have come later.

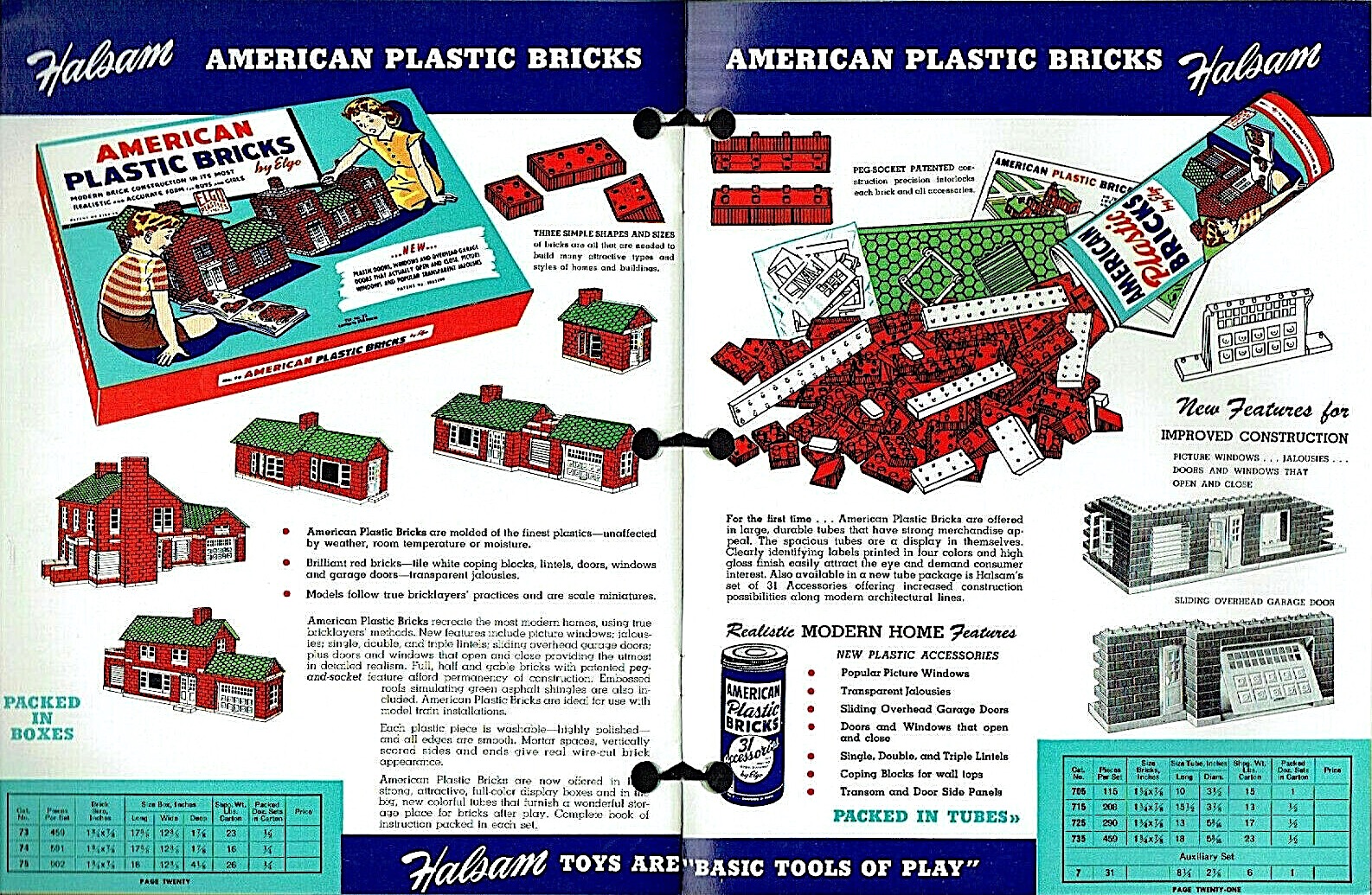

[Full page “American Plastic Bricks by Elgo” spread from the 1956 Halsam catalog. The company gradually de-emphasized the Elgo name in relation to the product]

“Modern brick construction in its most realistic and accurate form—by Halsam,” read a Christmas-time newspaper advertisement from that year. “An ingenious building set of inter-locking pressed bricks that make miniature models in true-to-life proportions and appearance.”

Interestingly, American Plastic Bricks and Kiddicraft both debuted in ’47, but it’s usually only the latter that’s honored with the title of “predecessor to LEGO bricks,” as Wikipedia puts it. Presumably, this is because the Danish toymakers at LEGO were “influenced” by Britain’s Kiddicraft before they’d seen Chicago’s offerings. But still, if it’s not clear by now, Hal and Sam have never really gotten the credit they’re due.

VI. Sturdy and Permanent

Keeping in mind that LEGO was still a non-entity in America through the entirety of the 1950s, Elgo’s American Plastic Bricks played a far greater role than the former in introducing Baby Boomers to the concept of snapping together their own miniature plastic cities. Admittedly, Elgo promotional materials also encouraged young builders to “cement together” their creations to make them “sturdy and permanent,” suggesting these early bricks didn’t exactly lock in place reliably on their own. But still, there was plenty of fun to be had and few limitations.

“It’s simply fascinating to build modern homes, schools, stores and all sorts of other buildings with American Plastic Bricks,” piped another 1953 ad. “. . . The perfect gift for children four to twelve years and older.”

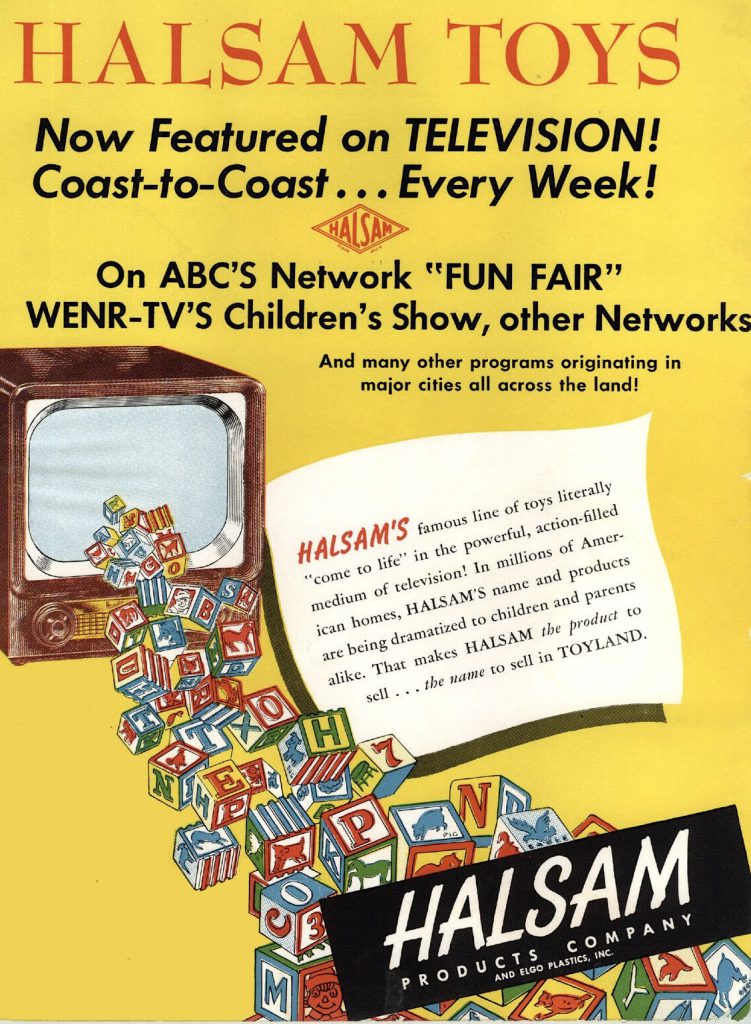

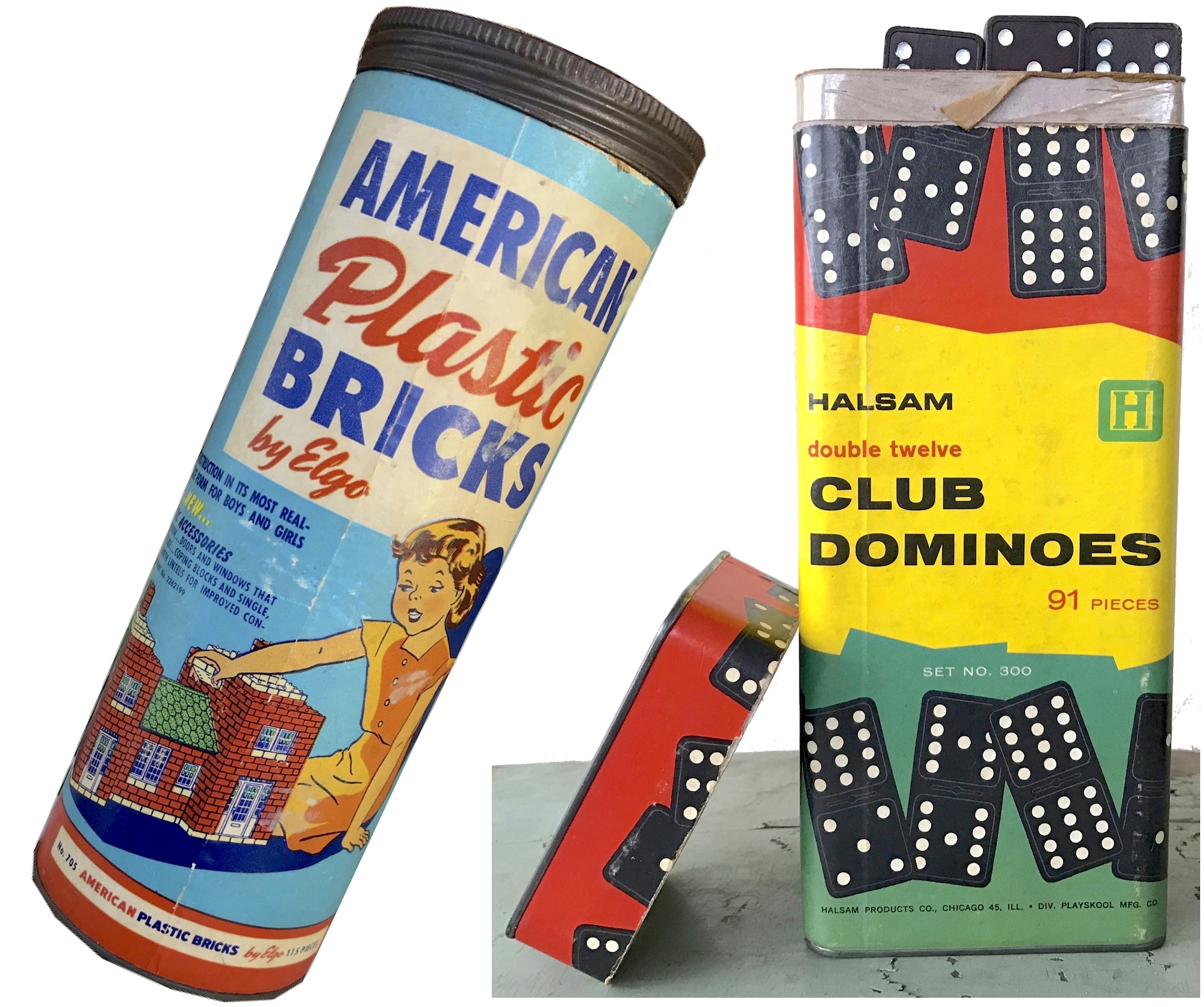

Unlike a lot of toys of the 1950s, Halsam’s bricks, blocks, and logs also catered fairly equally to boys and girls—both through traditional print advertising as well as the new medium of children’s television commercials. The American Plastic Bricks container in our museum collection is fine evidence of this unisex branding, as the artwork features both a cartoon boy and girl enjoying their own construction projects while barely tolerating each other.

Unlike a lot of toys of the 1950s, Halsam’s bricks, blocks, and logs also catered fairly equally to boys and girls—both through traditional print advertising as well as the new medium of children’s television commercials. The American Plastic Bricks container in our museum collection is fine evidence of this unisex branding, as the artwork features both a cartoon boy and girl enjoying their own construction projects while barely tolerating each other.

Men and women co-existed in fairly equal numbers at the Halsam factory, as well, where 175 workers were on the books in 1953—many of them focused on packing and shipping, since the plastic toys virtually manufactured themselves. Back in the ’20s, the company had filled its ranks largely with German-American craftsmen from around the Ravenswood neighborhood, but like the city in general, the diversity of the staff had expanded with each subsequent decade, and a lot of training was done on the job.

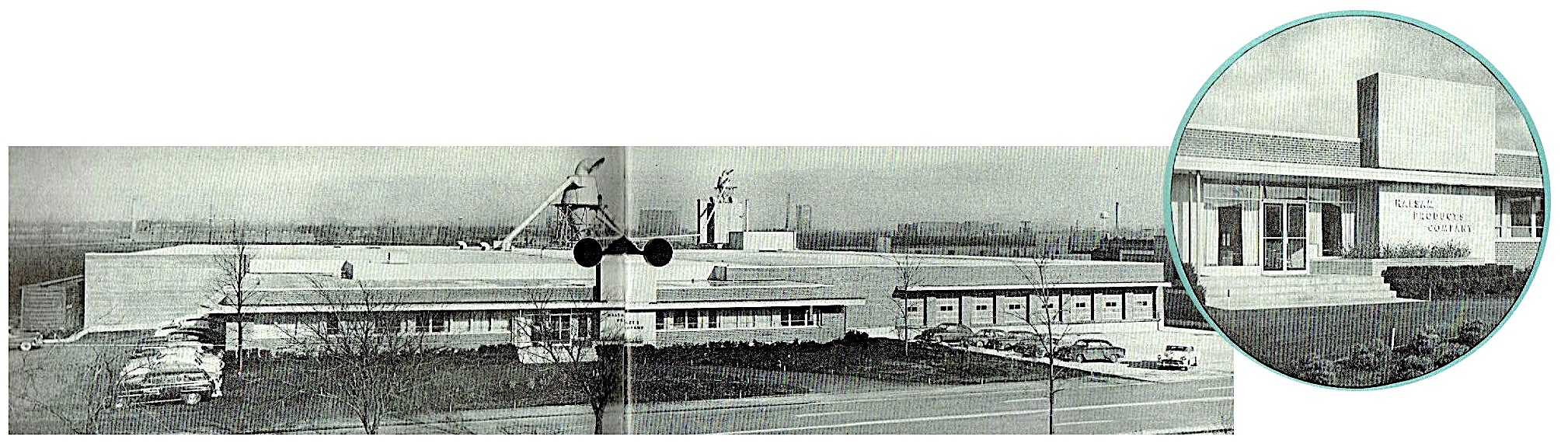

By the mid ‘50s, as the next generation of Gosses and Elliotts took on larger roles with the business (specifically Samuel’s sons Sam III and Bill Goss, and Hal’s son Kip Elliott), Halsam Products really reached the peak of its powers. In a particularly symbolic move, the company purchased its original wood block rival, the Embossing Company, which became a short-lived Halsam subsidiary in 1955. Around the same time, Halsam / Elgo outgrew its longtime Ravenswood plant, moving its workforce up the road to a larger, modern, one-story complex (107,000 sq. ft.) at 3610 W. Touhy Avenue in Skokie.

[Sprawling Halsam headquarters at 3610 West Touhy Avenue in Skokie, as it looked in 1956. The plant fell into disrepair and was replaced with a shopping center in the 2010s]

While Nils Paulson was still developing exciting new construction toys like the “Skyline Series” (the first skyscraper-focused toy brick set), the ’50s really saw a lot of creative attention paid to product packaging, with vivid colors and tall, tube-style boxes, including the rectangular Club Dominoes container in our museum collection, as well as the American Plastic Bricks mega sets.

“For the first time . . . American Plastic Bricks are offered in large, durable tubes that have strong merchandising appeal,” read a 1956 sales sheet. “The spacious tubes are a display in themselves. Clearly identifying labels printed in four colors and high gloss finish easily attract the eye and demand consumer interest.”

“For the first time . . . American Plastic Bricks are offered in large, durable tubes that have strong merchandising appeal,” read a 1956 sales sheet. “The spacious tubes are a display in themselves. Clearly identifying labels printed in four colors and high gloss finish easily attract the eye and demand consumer interest.”

The same 1956 sales sheet, sent out to potential Halsam Products distributors, defined the company’s mission statement fairly succinctly.

“Each product in the Halsam line must fit one definition: is it a ‘basic tool of play?’ If it is, then we have three great advantages in the highly competitive toy industry:

1. The child wants it . . . because Halsam toys fulfill children’s basic desire to build, to create.

2. The parent, who buys it, wants it . . . because the Halsam toy provides a natural, desirable outlet for children’s mental and physical energy.

3. You, the seller, want it . . . because being a basic staple toy the Halsam product maintains high volume sales year after year—all with the attractive profit structures which have made Halsam famous.”

VII. Too Cool for Playskool

During its time as a family-run business, Halsam never really altered its mission, nor did it experience a real concerning downward trend. Its old reliables—Safety Blocks, Dominoes, Checkers, and Disney tie-ins—were still going strong through the ‘50s, and the company was doing about $4 million in annual sales, with Christmas demands always turning the Skokie plant into a bustling Santa’s workshop of sorts. Harold Elliott had done well enough in life by this point that in July of 1959, his 65-foot yacht—named the Carolyn IV after his daughter—was briefly mistaken by Chicago TV crews for the Royal Barge of the visiting British monarch, Queen Elizabeth II.

There’s another story about a certain European visit to Chicago—at roughly this same time period—that’s been passed around through several copy/pasted Halsam histories on the internet, but doesn’t seem to have much hard evidence to substantiate it. According to this apocryphal account, there was actually a face-to-face meeting between representatives of Elgo Plastics (specifically Bill Goss) and visiting dignitaries from Denmark’s Lego Group just ahead of Lego’s entry into the U.S. market in 1961.

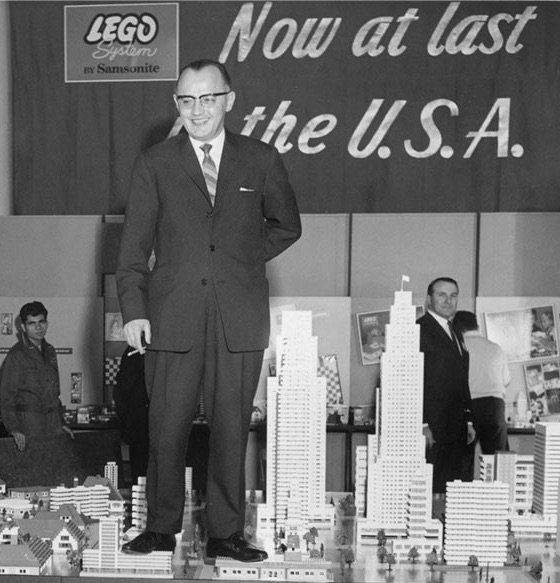

Lego’s new president, Godtfred Kirk Christiansen [pictured], was dead set on conquering America, and would have been very aware not only of a potential conflict with Elgo’s exisiting plastic bricks, but in the ridiculous similarity of the two company’s names. So, as legend has it, Lego agreed to pay Elgo the whopping sum of . . . $25,000 . . . to “square itself”—whatever that means—and thus storm the shores of the USA unchallenged.

Lego’s new president, Godtfred Kirk Christiansen [pictured], was dead set on conquering America, and would have been very aware not only of a potential conflict with Elgo’s exisiting plastic bricks, but in the ridiculous similarity of the two company’s names. So, as legend has it, Lego agreed to pay Elgo the whopping sum of . . . $25,000 . . . to “square itself”—whatever that means—and thus storm the shores of the USA unchallenged.

Whether that meeting ever happened or not, the way things played out in the 1960s certainly opens up a yacht-load of “what if?” scenarios when it comes to Lego’s rise and Elgo’s fall.

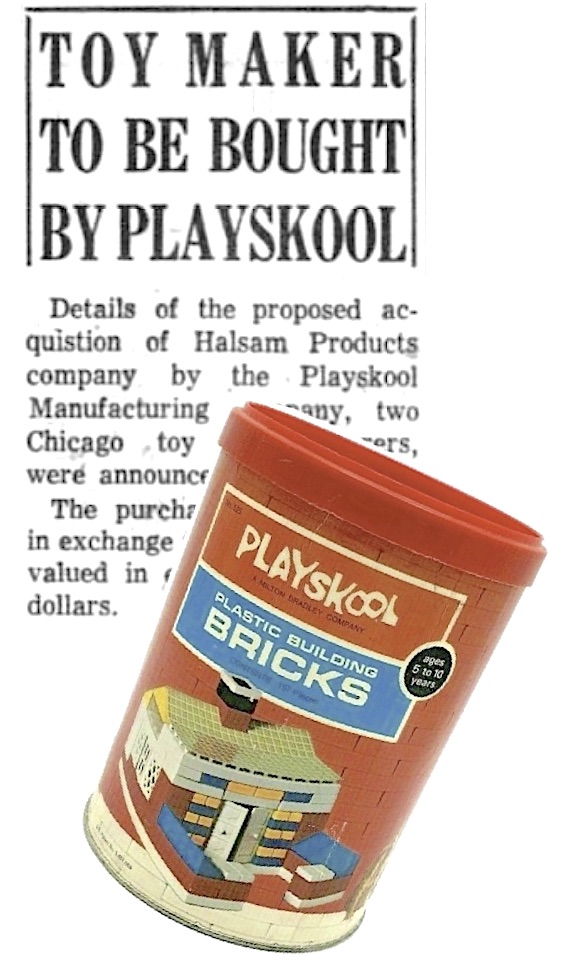

During a hugely successful Christmas season in 1961, the Tribune was already reporting negotiations of a merger between Halsam and Playskool—another Chicago toymaking giant. And by January of 1962, the deal was done. Playskool took ownership of Halsam, Elgo, and the Embossing Company in exchange for $3 million in Playskool stock.

Samuel Goss Jr. and Hal Elliott, both having reached retirement age, took places on the Playskool board of directors. At the time, they probably felt like they’d solidified the business they’d spent the past 45 years building, metaphorically “cementing together” its ability to meet the ever-growing demands of the toy biz in the future. Obviously, it didn’t work out that way.

Samuel Goss Jr. and Hal Elliott, both having reached retirement age, took places on the Playskool board of directors. At the time, they probably felt like they’d solidified the business they’d spent the past 45 years building, metaphorically “cementing together” its ability to meet the ever-growing demands of the toy biz in the future. Obviously, it didn’t work out that way.

While Playskool continued to manufacture Halsam-branded toys out of the Touhy Avenue plant in the 1960s—including American Plastic Bricks—a series of additional buyouts complicated the arrangement. After Milton Bradley took over Playskool in 1968, Halsam manufacturing was moved under Playskool’s own roof, and holdovers like Kip Elliott and Bill Goss (who’d been working as the VP of Sales and Marketing with Playskool) eventually moved on.

By the time Playskool opened its new Chicago factory in 1973, the Halsam name was barely uttered, and “Plastic Building Bricks” were sold under the Playskool brand only. When Hasbro subsequently purchased Milton Bradley in 1984, the closure of Playskool’s Chicago facility essentially buried Hal and Sam’s legacy for good.

In 2015, in unrelated news, the Lego Group collected over $2 billion in revenue, making it the largest toy company in the world.

SOURCES:

Goss: Proud of the Past, Committed to the Future, by Herman Kogan, 1985

“Flames Cause $100,000 Loss in Wooden Toy Factory” – Chicago Tribune, March 6, 1928

“The Halsam Line” – Playthings, December 1928

Halsam Products Catalog – 1956

Halsam Products Catalog – 1959

“An Aching Tooth Stops Queen for 20 Minutes” – Chicago Tribune, July 7, 1959

“Toy Maker to Be Bought by Playskool” – Chicago Tribune, Jan 30, 1962

Toys in America, by Marshall and Inez McClintock, 1961

“Halsam Products Co.” – All About Old Toys

“History of the Building Brick” – Imex World of Bricks

“Toy Building Brick” U.S. Patent 2262199A, Nils I. Paulson

I had sets of American Plastic Bricks, American Logs and Lincoln Logs as Christmas gifts

in the Late 1940’s or very early !950’s. The American Logs were superior to the Lincoln

Logs in my opinion. I have told many people that LEGO’s were basically a ripoff of the earlier American Plastic Bricks. I remember the American Bricks as being of high quality. I also had

a very large Erector Set, AC Gilbert Chemistry Set and a collection of Gilbert American Flyer

Trains. No wonder I became an engineer.

What years was the Fort America set made. I have seen these with plastic LIDO figures (as pictured on the box) and Tim-Mee Toys. Blue Civil War era soldiers and red Indians.

We had these bricks from the 1950s, and I never heard of Lego before the late 1970s. (The white plastic ones were sturdier than the red ones.)

I had the American Plastic Bricks along with Lincoln Logs while growing up in the 60’s. When I bought my first house in the late 80’s, it didn’t have a garage. For Christmas that year, my Dad had built me a garage out of the bricks. I’ve carefully moved the garage several times and it’s still together, just as Dad had built it. It’s been proudly displayed in every home I’ve owned since, usually above the fireplace! I found this well written article while trying to research the best option for gluing the pieces together. Thanks for the great article and the very helpful comments!

I’m 70 years old and remember enjoying the construction of buildings with American Bricks with my siblings in the late 1950s to early 1960s. We also did many other creative activities. My older brother was involved in building log cabins (not the toy ones), and my younger sister is an architect! My other brother (also older) loves making hand-crafted wooden items – especially electric guitar bodies. I like knitting and embroidery. My children had Duplo and Lego instead of American bricks. But I bet the American Bricks are somewhere in the house of my parents!

This is so interesting. Nils Paulson was my grandfather, we were surrounded by his many creative inventions and enjoyed them so much. He was a gentle man and a genius. It is great to get a bigger history of how things unfolded. Thank you.

I have two sets of American Plastic Bricks, Set No. 725, 290 pieces each set. These belonged to my husband and I would like to give them to my great grandson. If possible, can you find the date they were manufactured? Anything you can do would be greatly appreciated..

I would like to know the year Halsam acquired Gaston manufacturing company. I have a changeable Charlie puzzle and would like more information on the Gaston co.

Thank you thank you for shining the light on the best toy ever! I love everything about my. American plastic bricks. I’m 68, and my brother is 71, and we still play with our many sets of bricks. They’re entirely responsible for my architecture career. I remember trying to quietly pour them out in the middle of the night when I was no more than 3—ahhh, pure heaven! I have sets from every decade, including some of of my mom’s wooden ones from the 30s. Tubes of bricks are displayed on our mantle. Yes I am a brick fanatic. I just want them to get the credit they deserve. They were most definitely first, way before those other bricks. I hope my family believes me when I say I want my ashes to reside in one of those beautiful tubes forever!

I played with American plastic bricks in the 80s. My dad had fond memories of them and picked up 2 large tubes of them, and showed us how he and his siblings used them to make marble chutes. You couldn’t do marble chutes well with Lego back then, so we really loved playing with them. I dunno what happened to them after we grew up. Probably back in a yard sale. I hope someone else enjoyed them as much as we did.

Wonderful article! Thanks so much for making it available for so many to read. My brother had the American Bricks when he was a child, and as his older sister, I loved playing with them whenever he was willing to share. I can still feel the texture of the bricks as we carefully assembled buildings of our imagination. My brother turns 80 next month, so the event has prompted me to go in hunt for some of the toys that we played with during the 50’s for a trip down memory lane. By chance, I ran across this very thoroughly researched article you have shared here, and plan to forward a link to it, so that my brother can also enjoy reading about one of the toys of his past.

Do you know where to find a metal Halsam screw top for my American Brick set ?

Hello – I am helping my mother clean out stuff and I came across a Halsam “Constructioneer” set in a blue cylinder similar to the American Plastic Bricks shown in this article. Can anyone provide me with info regarding the “Constructioneer” set like what year it came out or what was included? Any idea of the value would be great too. I went thru and sorted and counted the pieces and there are 463! So its a huge set. No instructions or any info or date – just the Halsam logo on the tin of the container

I remember my parents buying these plastic bricks for us kids for Christmas. We played for hours building houses. These and Lincoln logs. Again played for hours with the logs. I came across a container of the plastic bricks at a ladies house and ask if you ever sell them I would like to buy them. She just gave them to me. So I took them to my brothers house and we started putting them together. I’m 78 years old. Sure brought back memories.

There are lots for sale on eBay. Be careful, some are the newer ones usually branded Halsam, not Elgo, which stick together and are awful to build with. You can tell which is which by looking at pictures of the bottoms. If the hold have a split in them, then are the sticky ones. Sticky ones have two problems: They tend to not go all the way on making the stack of bricks higher than windows or doors. Aldo, they are a real pain to tear down making you take each brick apart, sometimes with considerable effort.

I grew up playing with Elgo building blocks. Just got them out a few days ago for my grand kids and oddly enough there were 6 blocks in there that were smaller and had the Lego logo on them. How is that when the sets hadn’t been opened since my last play session which was probably around 1958?

Gary, if you ever want to sell that unopened set, I would definitely be interested. American Plastic Bricks were my favorite toy as a child in the late 50s and 60s. I have all the sizes plus the Halsam Army Bricks.

I’m 63 yrs old and don’t remember playing with the American Plastic Bricks but I found an unopened set from 1956 and the lady was only asking $8.00 so I bought them to add to the few other nostalgic item I display in my man cave. They’re on a shelf, still unopened beside my original Rock-em Sock-em Robots and erector set. After reading some of these comments maybe I’ll open them and see what my grandson and I can build.

I am 69 years old and enjoyed playing with our American Plastic Bricks along with my two older sisters in Gallipolis, Ohio during the late 50s and early 60s. Unknown to me at the time, my future bride – who lived two hundred miles away – was also enjoying her bricks with her close friend and next-door neighbor.

A few years ago, my wife, came across two tubes of the bricks in a thrift shop. We were in our early 60s and enjoyed playing with them together, often commenting that we wish we had them when our two daughters were growing up. We later added another “tube” to the set, so we now had a pretty nice collection of bricks.

Last weekend we had our two grandchildren with us. Micael is 7, and Hannah is 8, and we introduced them to the bricks. If anyone thinks that today’s kids must be plugged into some “device” to have a good time, I would love for them to have seen what took place in our family room last weekend. There were competitions that pitted the “girls” vs the “boys.” There was a combined effort that produced a spectacular brick home – complete with brick furniture and battery operated interior lightning (made possible by the little 10 & 20 LED lights of seasonal items such as snowflakes, and snowmen), but most importantly, there were two kids having the time of their lives playing with toys that were 60 years older than they. Their creativity and imaginations were on full display for hours.

As a side note, only one of our sets had the “coveted” garage door, but the frame was hopelessly warped. Michael and I carefully tried to resurrect it with a heat-gun, but the plastic shrank and it only made it worse. That was not a major problem because the door was already unusable, but it did cause the two of us to go to ebay for a little “brick searching.” We found a set with a door that looked to be in good shape and ordered it before they returned home.

The set arrived yesterday and the door was perfect. Last night, Jayna and I stayed up past midnight, creating a new home, complete with a place to safely park our car! We texted pictures so the kids would see it early this morning. We will have Hannah and Michael over in a couple weeks and I am sure you know what will be on the agenda!

Wondering about the history of Halsam and Elgo, we stumbled across this website early this morning. We would like to say thank you for the wonderful research about these amazing products and the families who developed it. We had no idea. We enjoyed everyone’s comments. If we had our magic wand, we would fast-forward these exact products and put them on today’s shelves of Target, Walmart, and, of course, Crackerbarrel.

Oh, my closing comment. Lego? You can have them. Nothing beats the American Plastic Bricks – for all the reasons many of you shared as well as all the reasons we saw last weekend.

I have a HalSam dominoes color dot set of black/dragon no.622-R, 28 pieces, in a cream and turquoise box design.

Would you know when it was first available?

Thank you,

Pat Maus

https://www.youtube.com/watch?v=FQko4HGMO6o

A page dedicated to creating old and modern constructions with american plastic bricks

The Games that Built America was on recently – LEGO bricks were the main topic but I knew back in the 50s – PRE LEGO – that I had a cardboard cylinder filled with bricks, etc. that I loved playing with. Time to google and I found this page. Sure enough, I wasn’t having delusions about another brick toy and was excited to find info. Brings back lots of fond memories. I can’t wait to read through all the other comments.

I have always loved American Bricks. I am 60 yrs old and just picked up another 1500 pcs at an estate sale today of both Halsam and Playskool style bricks. I have about 9500 pcs of all kinds of pieces. What I need is roof sections in good but I wish I could make my own. Keep collecting people. Have Blessed day.

I had a set of American Plastic Bricks somewhere during the mid to late 1950’s when I was 7 to 10 years old. I thought I had remembered that I had the second to the largest set out of five available sets. However, after checking the information in this article, I realize that my memory is incorrect. Is it possible to list ALL the sets available, both in boxes and tubes circa 1957-1958? This information would help me in writing a family history of that period to keep for all of us. Thank you.

As a youngster in the 1950s I had a large and small tube of the red plastic American bricks with the windows, doors, garage door and everything and really enjoyed it. I saved it all these years wondering if anyone besides me ever appreciated this. Fast forward to March 24, 2022. My neighbor picked up a lot of his boyhood toys from his out of state dad and showed all to me. Lo and behold he had three times as much of ALL the brick pieces and parts as I had. I offered to buy but because I had done some bartering with him he GAVE it all to me. These bricks are totally the same size as mine but they have the slotted holes that “pinch” the part below and I do like this better. What are the chances that after 60 years these are combined.

My grandson (15) and granddaughter (7) spend hours assembling things with the original guides I still had. Now I no longer wonder what to do with them and who gets them one day!

Excellent article, thanks for the fun read!

Concerning “these early bricks didn’t exactly lock in place reliably on their own”. It’s true the earlier bricks did not lock, but gravity held them together quite well so long as one was careful not to bump the buildings. (Personally, I thought this taught me the value of being careful with my toys.) Yes, the instructions encouraged gluing the pieces together to make the buildings permanent. Of course, if you wanted to build anything new you would have to buy another set of bricks from Halsam.

The later bricks from the 60s did stick together. I didn’t like them much, because disassembling a building brick by brick was rather tedious.

A number of years ago, I built all the models from the 1953 instruction booklet and photographed along the way.

https://www.flickr.com/photos/27742455@N06

I also preferred the early non-locking bricks — crashing your Tonka truck into your completed house was half the fun (and it was easier to put away.

Another factor that made American Plastic Bricks superior to Legos was that they were easier on Dad’s bare feet when he stepped on them.

My cousin and I spent hours building houses that could withstand a rubber tipped rocket than came out of a spring loaded base – of course this resulted in a lot of broken bricks. We also built house boat type structures that we zoomed across a smooth floor, over an inch or so drop and finally into a cabinet- these had “suspensions” – amazing what you could do with the bricks. The ones that stick together (which I’ve just recently encountered are awful to build with) and would have made those games impossible.

I have 2 16 page catalogs of “How to build with Halsams constructioneers “. And also some of the plastic bricks ,maybe 40 pieces windows doors etc. richardehcnalp@yahoo.com if your interested. Live in Oregon.

Growing up in Oregon, my only wish at Christmas time to my parents was another set of American Plastic Bricks. I would build many houses, being careful when it was time for demolition. I played with this toy for about 5 or so years, after which I went to college to be a draftsman. I got my degree and after several jobs thru the years I decided to try my hand at designing homes. I did this for 20 years in the Portland area, designing many a home – about 2000+. I owe much of my success to this product. My sister still has the bricks at her place, she saved most of our toys from that era. I will be 70 in a couple of months, and I still look back fondly of that toy.

Would anyone be interested in a poster that advertises the American Bricks. It’s just like one of the pictures up above with the blond girl in the bottom left corner and a brown haired boy in the right corner with the red house in front and a city skyline in the back. My grandmother used as a backing for family pictures that she framed! I just took apart to scan the photos.

Hi Susan, would you be able to email a photo of the poster to us at contact@madeinchicagomuseum.com? We might be interested!

I would definitely be! My fiancé is Bill Goss’ grandson. He would love it! Gabbymjones@gmail.com

I would like permission to print this history and pass it on to several folks in their seventies who like myself (age 78) who have obtained several sets of Halsam/Elgo and are enjoying a ‘second childhood’. Also to youngsters whom I have given complete sets to.

– Edward Herbst

You’re certainly welcome to print out the article, Edward, as long as you don’t publish it elsewhere or present it as your own.

I just came upon an item produced by HalSam. It is a box of “Double Nine Dominoes”. I am interested in finding out when this particular product was manufactured. After looking at E-Bay, there are many different kinds of dominoes sets that they manufactured over the years. This one appears to be pretty old. The artwork on the box is a red dragon and yellow bird (crane?) against a blue background. In looking at pictures on E-Bay, my set of dominoes has various colored dots and the ones listed on E-Bay are just white dots. There is also a number 920-HR on the box. Wondering if anyone can help me out. Thanks in advance…Merv

Hello everyone, what a privilege to be able to read these stories, I created a YouTube channel in which I make designs based on American plastic Bricks, showing that several years later they are still valid and that their pieces remain in the memory of all of us, I try to demonstrate that although time passes, the only limit is our mind and creativity, and that the plastic bricks developed by Elgo and Halsam are in a very high place among us, the tradition endures and has become a beautiful legacy, I leave you my link in case you want to see it.

https://www.youtube.com/channel/UCTHCvQdIz7V7On4Ern6-vZA/videos

Hello All,

I am Carol Elliott Sewell’s daughter, Maryann Sewell Charmoz. I have throughly enjoyed reading this concise history of my family’s toy company. I own many of the toys, in their original containers. My granddaughter loves to play with the Elgo bricks and the American logs. I remember as a child being so excited at Christmas when I received the largest tube of bricks!

I am the Grandson of Harold H Elliott, and son of Harold H (Kip) Elliott, Jr. I have seen a few stories about Halsam/Elgo and enjoyed the accuracy about my family history and a manufacturing icon in Chicago. Samuel Goss Sr. was my Great Grandfather and had an impact on the world of news and information that became so critical in that era. I am proud of our lineage and hope to see more published in the future for my descendants. Thank you for putting this out there for all to see.

At Christmas 1960 my parents bought a set of Halsam Original Axe-Hewn Square American Logs for me, and a set of Halsam American Plastic Bricks (the improved version) for my brother. We still have both sets. I have a copy of the instructions that came with the Bricks (16 pages), and have made a color digital copy of them. I am not very good with technology. If someone with the expertise is willing to put these instructions online, I will be happy to mail my digital copy to them for this to be done (I assume there is no problem about copyright). Otherwise, I no longer have the instructions for the Logs and am unable to find them online. If anyone has the instructions for the Logs, it would be useful to put a copy online and let us know. Thanks. Farris Cadle fcadle@bellsouth.net.

Years ago my son was given a Pegboard Playtile Set 23. After he outgrew it I saved it for future generations in our family. Somehow, though, the pegboard itself got lost and now I have only the tiles! Do you still make this toy and do you have the pegboards that you could sell one separately? There are now three grandchildren who I think would have fun playing with it.

Thank you,

Sammye Wood

Sammye, we’re a history museum and have no connection to Halsam Products, which has been out of business for many years. Your best bet would be to seek out a pegboard on eBay.

I have a set of Halsam Original Axe-Hewn Square American Logs that my parents bought for me for Christmas in 1960. I no longer have the instructions. Does anyone know of an online copy of the instructions? Thanks.

Were you ever able to obtain a copy of the instructions? if so, would you be willing to share where you found them?

Is the cylindrical tube of any value to collectors ?

The cylindrical tube is of value to pure collectors, (ie they display it on a shelf) with or without piece contents. The tube must be in very good condition to be of interest to a collector. Personally I am more into building and rarely use the storage tube in any manner.

The “American Brick Blocks” set is referenced in the “Sears Roebuck” Catalog for Christmas 1937.

A few days ago I bought two Building Sets called “American Brick Blocks” from the American Company “Halsam” and that apparently was the predecessor building set to the “American Bricks”. According to the Instruction Booklet, the Date code for this set is February 1936, and from what I have investigated, the company manufactured it until 1939, the year they created the “American Bricks” brick system.

The sets of “American Brick Blocks” had 8 different pieces of wood of different shapes that were secured by means of cardboard fibers that were intertwined in each of the pieces of wood which had grooves for this purpose. Each piece of wood is stamped on one of its faces a series of Red Brick Blocks, and additionally they had cardboard doors and windows, which were secured by means of tabs to the grooves of the wooden blocks. Apparently this was one of the first Construction Sets invented by the Swedish Engineer Nils I. Paulson, since according to the Game Patent, it was requested by “Halsam” on May 13, 1936 and the Patent application was granted on May 16. November 1937, almost on par with Nils Paulson’s Invention of the “American Frontier Logs” Construction Set. The “American Brick Blocks” set is referenced in the “Sears Roebuck” Catalog for Christmas 1937.

I have a bag of bricks to make the house that I played with from the 1930s. My dad was born in the late 20s and they were his. I loved how the windows opened and the wavy window! Such memories for me. I am about to go down to the basement and unearth them as the last time they were used was when my children played with them in the early 2000s!

I have several sets of Halsam American Logs from when I was a kid. Each container indicates how many total pieces there should be but does anyone know how many of each specific piece there should be for Sets 805, 810, 815, 820, 825, 830 and 835?

I have a 1930s Halsam Rainbow Domino boxed set with the instruction sheet. I have only seen sets with an angel on the back of the dominoes but my set has The Capitol building on back. The back has no “owner name” but entire set, box & rules are in good condition. On the box, top left, there is a gold diamond with #650 inside.

Do the very early halsam blocks contain lead in their paint

I grew up with a used set of American Plastic Bricks that I played with A LOT until I sold them all at a garage sale when I was a senior in high school (I felt too old for them). I never played with LEGO, which I found to be derivative, overpriced, too colorful, and lacking the brick effect. A few years ago I felt nostalgic and bought a number of sets on eBay and relished in playing with them all – including “new” pieces that were not part of my original set(s). The loose-fitting nature of them never bothered me (similar to the other commenter, I kinda liked how it challenged me to be careful), but my grandkids didn’t like them at all. I bought some LEGO for them, and now I’m converted.

Hi! This game have a lot of fans in Colombia. In the 70’s American Bricks was licensed by Industrias Estra (Colombian Company). This company manufactured and sold the game in Colombia under the name “Estralandia” until late 90’s. In 2019 “Estralandia” was reedited andnow is back to the market.

Are they made in plastic?

As one commenter said above, I also knew these building sets here in Colombia (American Plastic Bricks) as “Estralandia”, which was basically exactly the same “American Plastic Bricks” sets that “Playskool” designed when it bought the rights to ” Halsam “in 1962. Industrias” Estra “from Medellín Colombia bought the rights to” Playskool “in 1970, and since then manufactured the sets until approximately the beginning of the 90s. From November 2019, Industrias” Estra “returned to launch the game, with some very slight modifications to the builds from the original 1962 “American Plastic Bricks” manual.

Last year I met another of the Construction Games of the defunct company “Halsam-Elgo” called “American Skyline”, which for my concept is one of the best Construction games that I have known, with which they can be specially built High-rise skyscraper. I consider it to be one of the best construction games because the constructions are very real since the pieces include floors, stairs, window panes, clocks of various sizes, flags, among many other things. Unfortunately these “Halsam-Elgo” sets were manufactured for a very short period of time (1956-1962). Fortunately, between last year and this year, I have managed to buy many sets in very good condition and very complete, to the point that I have the equivalent of almost 5 sets of the largest ever made.

Another of the “Halsam” Construction sets that I just bought but that I still do not have here in Colombia is “American Brick Blocks”, which I have investigated was the construction game that was the predecessor to the “American Bricks”. Apparently it is a construction set from the mid-1930s, which were made of wood, as well as the “American Bricks” that were the successors of this set.

I recently watched a Youtube video from an American collector who did an unboxing and comparison of the Estra Landia sets to the Halsam/Playskool sets. He observed the EstraLandia American Plastic Brick sets were virtually identical to the original Halsam sets of the 1960’s and Playskool sets from the 1970-1980’s. Watching the video I did notice a slight difference in the door(front/back door not garage door) in Estalandia sets. I wonder if Estralandia ships to the USA? I still have my Halsam sets from the mid 1960’s but always looking to add to my collection.

I received a complete 723-piece American Skyline set for Christmas in about 1956, when I was seven years old. It’s described in my forthcoming memoir about growing up poor in rural Pennsylvania. I’m a former Reader’s Digest editor now retired in Blairsville, Georgia, USA. Please contact me — I’d like to trade notes with you about this remarkable construction set.

I lucked into this article and want to thank you for it.

A noted academic chemist in our city has a you tube video about the development of the plastics used by Lego, and he repeats the claim that this type of brick was invented by the Danish firm. I doubted this was true, and I decided to check it out. I also knew that a business in our city (Mega Bloks, now a Mattel brand) had beaten back a legal challenge by Lego that suggested that their patent was far from original or unique.

I and my brother own 2 sets each of the original WOODEN American Bricks with the boxes and directions, and I wouldn’t part with them for love or money, even though our local architecture museum ( a world class outfit) would like to have a set for their collection of architectural toys.

Grand-kids, which are huge Lego fans, love to play with these bricks when visiting, which we encourage but not for reasons you might think. Because they cannot interlock firmly the children develop a much more realistic sense of the forces at work in the real world. Building something complex turns into a real challenge, but one that can be managed. The windows and doors have those fragile tabs, of course, but handling things carefully is another skill that needs to be inculcated in our small fry!

Mind you, my brother and I used to send a well-made windup tinplate tank (“Made in the American Zone” of occupied postwar Germany) complete with blazing lighter flint machine guns, against these structures in an attempt to level them. Like many parents that had lived through the real action in Europe, they didn’t approve. The destruction of a nice building by the accidental derailing of our speeding die-cast Lionel locomotive-led train on a curve and the resulting crashing sound was tolerated, of course.

I too played with sets as a child but in the early 1960’s. Yes the 1960’s era parts are different(improved for building) than the 1950’s era parts. The 1960’s parts have a groove cut in the bottom of the sockets to facilitate a much better grip. This was done on all the bricks and Lintels too. The window notches were improved also which facilitated considerably better functioning. The 1960’s era sets had the garage door frame and garage door as new parts as well.

I have a long history with American Plastic Bricks as I received and played with several sets as a child in the 1950’s and still have them to share with my many grandsons. Recently, I purchased on Ebay a couple of sets from the early 1960’s as a birthday gift for one of my grandsons and discovered that the bricks were slightly modified from those of the 1950’s era. The 1960s era sets had differently configured “sockets” underneath so that they better gripped the held together more tightly. (Less opportunity for earthquake destructions by shaking the table underneath a building…) In addition, some of the doors and windows were also different (solid doors, smaller picture windows, diamond windows, glass block windows, etc.) and there were a few old parts deleted and new parts added to the mix. I have two closeup snapshots of the newer bricks and other parts if there is a way for me to upload these photos.

I also played with American Plastic Bricks as a child, but in the 1960’s. My sets already had the improved brick design you describe. They stayed together much better. I purchased some of the older design bricks on ebay and did not like them. Generally, the Elgo brand(which was part of Halsam) has the older design for bricks and windows.

I use elmer’s glue to keep the older bricks of the fifties together even after they dry if I want to reuse them I let them soak in hot water and then clean them and reuse them the same way over and over. As long as you don’t use a bonding agent that molds into the original plastic itself you’ll be fine to reuse them over and over you just need patients and a good toothbrush to clean them in between. 😆

The windows and doors of the american bricks will not stay put when building a building and quite frankly, it is frustrating to say the least. I am an adult who had purchased this for myself. the pegs could be a bit longer and a longer triangle pieces could be lengthened. These need to be refined.

Unfortunately Halsam has been out of business for about 50 years, so no such refinements will be forthcoming.